Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

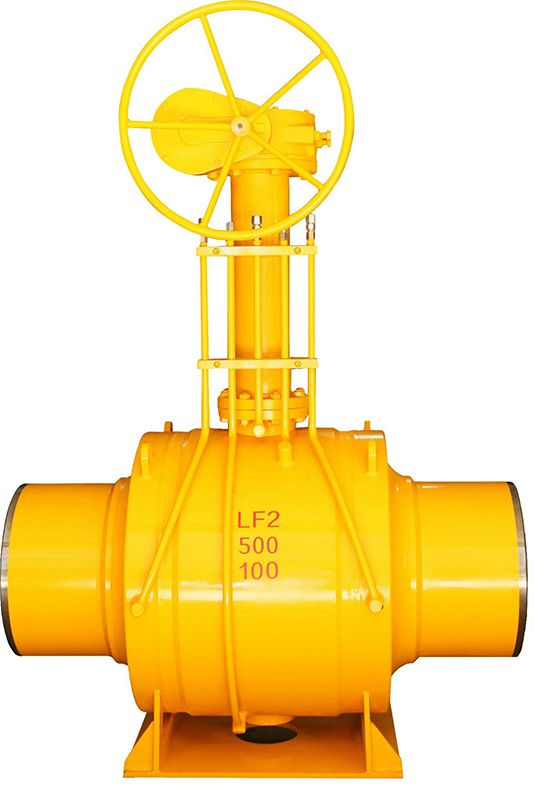

FULLY WELDED BALL VALVE

All welded ball valves can be used at any time and continuously in all types of weather conditions. They can be opened and controlled by needle ball or valve stem, or by clockwise rotation.

Product introduction:

All welded ball valve is a common component of industrial plant, which can be used as closing valve in process. They can be opened and controlled by needle ball or valve stem, or by clockwise rotation. All welded valves can be used at any time and continuously in all types of weather conditions.

All welded ball valves are ideal for handling abrasive and corrosive materials and fluids susceptible to nickel leaching from other alloys. They can also meet higher pressure and temperature, and have better sealing performance and longer service life compared with standard valves made of other types of materials.

The all welded valve body has a multi-functional and precision ball valve, and the ball provides high-quality performance in current water applications. The body valve is made of 10% copper, which is durable. The sphere is made of polytetrafluoroethylene, which is corrosion-resistant, corrosion-resistant, corrosion-resistant and corrosion-resistant. Ball design, manual tight port, high, only 1/4 NPT internal thread, automatic tracking with external thread fittings.

Product advantages:

The product is durable, with complete functions and general performance. Because it is a fully welded design, the welded ball valve has a wider range and can be operated for a longer time, so it is more capable of operating or the driver can perform manual operation or the electric driver can perform any position and position.

All welded ball valve is a good choice. It is composed of independent components through welding or welding weak connection. This process will produce points and valve positions. All service life of all welded ball valves. These tubes, so no joints will fail. Continuous monitors are pressure tested and certified by an accredited testing laboratory. They are available in standard industrial sizes with npt/bsp connections, including female connections.

Product design: the all welded valve is designed to withstand the most evil environment. They are made of carbon steel and are completely welded with stable performance. Ball valves are manufactured in and use quick connect fittings without any effort. The installation of the product does not require any special tools - just compromise or provide equipment.

Product design:

Global valves are designed to be corrosion resistant and reliable for many years of use. Each ball can be tightened with a tool. There is no need to worry that it can be installed vertically or horizontally. It also allows us to operate or operate the valve manually. Our full line of ball valves are designed with the highest quality and service life in the industry. Combined with these features, the ball valve has long service life and high value, and can provide the previous trouble free service.

The full valve assembly has anti vibration and anti impact capabilities, excellent transmission characteristics and easy-to-use design performance. It is 16 inch intuitive. Metallurgy is obtained by heat treatment after quenching. Welding steel products with standard strength can be used for correct impact and tensile strength. The all welded ball valve is an effective solution for providing water, oil and solutions. Due to the effective design, it is the choice for applications that need a high degree of security.

Advantages:

Fully Welded Ball Valve (welded body ball valve) gives it maximum strength at minimum weight as well as maximum resistance both to pipeline pressures and stresses. The compact, spherical design also eliminates body flanges, thus reducing overall size and leak paths.

Fully Welded Ball Valve (welded body ball valve) are ideal for buried service applications to decrease potential leak points and reduce the potential of fugitive emissions from flanges.

As one of the reliable Fully Welded Body Ball Valve manufacturers in China, Relia supplies welded body ball valves which are used mainly in Gas transmission and distribution pipeline (Mid-stream), typical for underground and buried installation.

Various testing procedures are used to confirm the tightness of the entire ball valve. Furthermore, weld seams undergo visual, magnet particle, ultrasonic and – if requested – radiographic testing.

Fully welded ball valve (welded body ball valve) is trunnion mounted, high-strength forged stems are located in PTFE impregnated stainless steels bearings for smooth operation. Trunnion mounted stems absorb the thrust from line pressure, preventing excess friction between the ball and seats, so even at full rated working pressure, operating torque stays low.